What is laser cutting?

Laser cutting is a method of obtaining the most precise shape from a sheet of metal, profile, or pipe. With this method, we separate the material by melting and evaporating it with the help of a laser beam. Thanks to this method, the edges are smooth without the need for further processing. This method is fast and saves time and material because we can accurately position the pattern without leaving unnecessary material waste.

Laser cutting of sheet metal, pipes, and profiles.

We can use the laser to cut sheet metal, pipes, and profiles. We can cut any shape in sheet metal that we can enter into the laser program. The cutting of tubes has never been so precise as laser cutting. Profiles are also shaped using lasers. All cuts are addressed to different needs and applications. We, as a company, would be pleased to meet your requirements and cut all designs for you. We create cutting-edge solutions for every industry, according to your needs.

Laser cutting is one of the processes by which we can thermally separate material, and it is non-contact. The laser beam strikes the surface of the material and heats it until it melts. The whole process follows a geometry which separates the material. For laser cutting, we need technical gas. It is the most efficient method as it does not crease or distort the material it works on.

Sheet metal laser cutting accuracy is high.

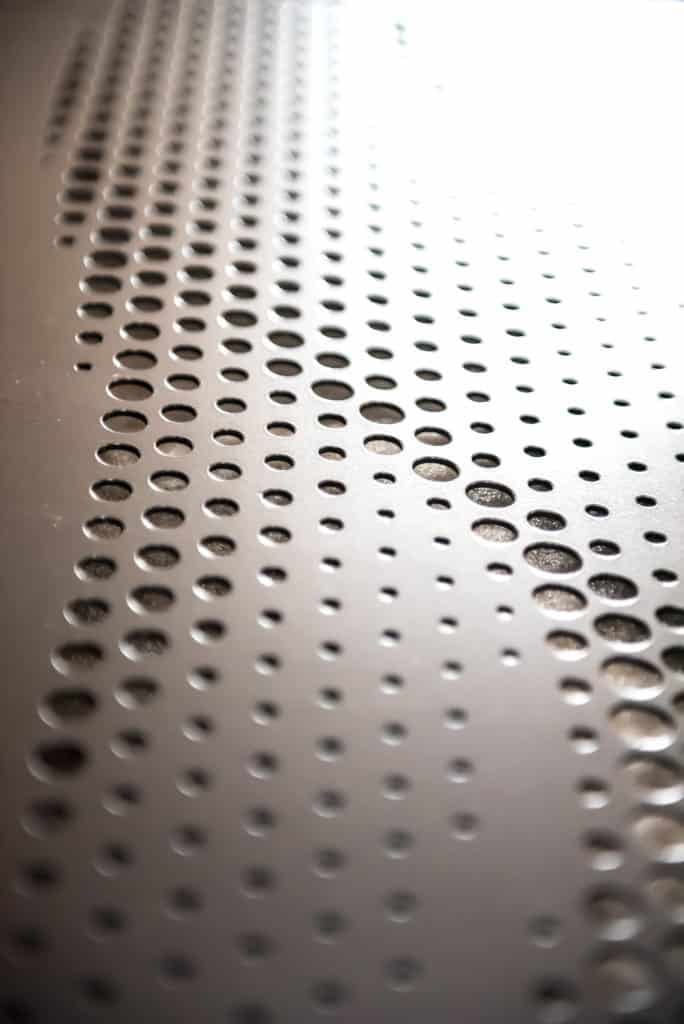

We can laser-cut all the materials that are used in industrial processing. When it comes to metal sheets, we can precisely cut them from 0.2 to 30 mm thick. It is thanks to this possibility that the laser is the number one tool for cutting such surfaces. We can cut details with an accuracy of 0.001mm. This is the most precise method, which saves time and material. Due to its precision, laser cutting does not require additional processing.

Accuracy of laser cutting of tubes and profiles

What kinds of pipes can we laser-cut? These are pipes with diameters of 12 to 240 mm. Profiles, on the other hand, have a minimum dimension of 12x12mm and a maximum dimension of 200x200mm. The precision of cutting is 0.2 mm. Cutting profiles and pipes has considerable advantages over conventional machining. The laser is the most accurate device for cutting profiles and pipes. Laser cutting of tubes and profiles is one of the best methods of obtaining the desired shape and the appropriate angle of cut available on the market.

Precision in laser cutting

The precision of laser cutting is based on the use of a suitable cutting agent, which in our case is a hot laser beam and pure technical gas. The accuracy level of such a beam is 0.009 mm. Thanks to the repeatability of the process, we have a negligible amount of waste, regular shapes, and a relatively short process execution time. The laser’s precision allows it to cut the smallest details and patterns, which is one of the advantages of further applications.

Laser cutting quality

The quality of laser cutting is determined by geometrical measurements of the cutting edge and surface shape as well as by mechanical and metallographic tests. The quality of laser cutting is always at the highest level. Thanks to such cutting, the edges of the workpiece do not need further processing, which accelerates the production process. Regardless of the complexity of the workpiece shape, we can carry out any order.

The 2D laser enables us to process a large number of materials of different thicknesses. Thanks to this laser, we can obtain parts in the most diverse shapes during efficient and precise laser work. These modern machines with 2D technology have many applications. They are dynamic, efficient, and effective. Cutting with a 2D laser avoids deformations, and the cut is accurate and constant. The 2D laser’s primary application is the cutting of metal sheets, not only thick and oversized ones but especially flat ones.

It is very often necessary to use spatial processing, which is possible thanks to the 3D laser. Using this laser, we can process not only metal sheets but also profiles and pipes. The most important thing is that this technology makes it possible to cut out different shapes of a workpiece without the need for amendments, and the production process is much faster, more efficient, and more effective. This technique is used by many industries because of its precision.