laser cutting Birmingham

Express laser cutting service Birmingham

Regardless of whether you are an individual client or a big company, we offer fast work execution and attractive terms and conditions of cooperation. All orders are equally important to us. Our experienced employees also perform a quick valuation and undertake any, even the most complex, laser cutting projects. Therefore, if you need a responsible contractor, you should contact us today!

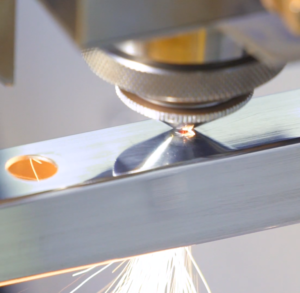

We use the best quality equipment, which is a TRUMATIC laser, as well as a cutter in the L-3050 variant with a power of 5 KW. These machines are characterised by extraordinary cutting quality and accuracy in details. This equipment also allows for cutting metal sheets up to 25 mm thick. Even though laser cutting is a thermal treatment, this process does not cause any deformations or losses in the material. Engineers, artists, and designers use laser cutting, inter alia, for the production of prototypes or simply as a method in industrial production, which guarantees the repeatability of all cut details and elements.

If you decide to choose our company, we will guarantee you the knowledge and experience of our qualified employees. It is also very important that we have a modern machine park with extensive facilities and materials of the highest class, recognised all over the world. As our employees are involved in training and many projects, they will perform the most complex tasks and handle the most advanced and complex equipment. Thanks to our paying attention to each order and timeliness, we collect positive feedback about our work.

- Laser cutting-the biggest advantage of this solution

Laser cutting is an innovative way of processing a variety of materials, not only metal. Regardless of the raw material, the quality of the cut edge will be at the highest level. The directed beam precisely hits the marked area on the project. For this reason, it is not necessary to spend time or resources on any finishing stages. The technology ensures the highest quality and repeatability of details. At the same time, there is a particularly low risk of damage the product. Therefore, there is no material loss.

Our well-trained and experienced team uses a TRUMATIC laser to cut sheet metal. A professional cutter, model L-3050, achieves a power of 5 KW. The machine is characterised by unsurpassed quality and precision of work. The greatest thickness of the cut sheets is as much as 25 mm.

Although cutting metal sheets with a laser is a heat treatment process, it does not cause any distortion or loss of metal. The laser is used by engineers as well as designers and artists. It can be used in the preparation of prototypes and also in industrial production. We always guarantee 100% repeatability of the cut elements.

Laser cutting is a modern solution

If you want to process materials, not only metal, laser cutting is the best and most innovative way. The quality of the cut edge will remain at the highest level, no matter what product is processed. This method allows for repeatability and accuracy of the cut elements and a low risk of material damage, which prevents the production of material losses. Moreover, finishing the product will not require a lot of time or resources.

Accuracy and laser cutting of steel

Metal processing by laser cutting stands out from other methods, such as plasma or water jet cutting. Adjusting parameters to individual expectations and projects enables numerical control. It can cut not only simple but also complex shapes. We will ensure fast execution of work, timeliness, and accuracy in the performance of work. We know that our clients pay special attention to it.

The entire laser cutting process is carried out remotely with safety in mind, as a strong beam of light is concentrated on the surface of a few millimetres. In addition, the machine’s software allows changes to be made at any stage of production if there are any sudden changes to the design. This saves a lot of time and money.

Laser cutting enables more than just sheet metal cutting. It also allows you to screen products. The surface of the material is heated and its top layer is burned. This modifies their appearance.

BIRMINGHAM'S HIGHEST QUALITY PIPE, SQUARE PROFILES, AND TUBES CUTTING SERVICES

Are you looking for a real professional company in the field of metal processing, whom you can confidently entrust with the laser cutting of pipes and profiles? If so, you’ve come to the right place! ELEKTRON is exactly the company you need! We have extensive experience in the implementation of both large and complex orders for wholesale customers, as well as working with smaller industries and companies for which we make cuts for specific needs. Therefore, do not be persuaded any longer and take advantage of the best variant available to you: 3D laser cutting in our company!

Full professionalism and the latest generation of equipment!

We perform laser cutting of pipes and profiles in our machinery park, using a high-class TH65 IPG YLR-2000 W cutter from one of the most valued companies in the industry for its solid construction and precise cutting Laser. It enables laser cutting of pipes and profiles of various lengths and thicknesses, as well as made of various materials. In our offer you will be able to find two different types of services related to laser cutting of profiles: laser cutting of square profiles 20 × 20 and 150 × 150 with a length of up to 6500 mm; and 3D laser cutting of other tubes with a diameter not exceeding 210 mm (e.g. 150 × 20 mm). Our professional equipment has the option of automatic loading (3600-6500 mm long) and material unloading (3000 mm), while the maximum thickness of the cut varies depending on the material.

The maximum thickness of the cut elements depends on the material they are made of. Below are the values for the most commonly used materials:

The maximum cutting thickness of the cutting machine:

- – Black steel – 8 mm

- – stainless steel – 5 mm

- – aluminum – 3 mm

- – brass – 3 mm

- – copper – 2 mm

Of course, these are not the only materials that we cut, and we also work with chrome-nickel or stainless steel pipes and profiles. This wonderful machine and the skills of our employees are two aspects that allow our company to stand out from the competition!

Contact us today!

If you still have any doubts, please contact us directly. We do not only care about the performance of the task but, above all, about the satisfaction of our contractors, which is why our staff conducts consultation interviews to meet the needs and requirements of potential customers as effectively as possible. We will advise you on what parameters to choose, estimate the time of order completion, and make sure that you are satisfied with the price and professional customer service!