laser cutting Manchester

We are a modern company based in Poland, dynamically developing in the UK market in the field of metal processing. We are currently working with many companies, both in Great Britain as well as France and Germany, which provides excellent and effective cooperation opportunities.

Elektron offers our clients the performance of all services related to steel structures, production and mass metal processing services.

A qualified team, the use of modern and innovative technologies, and a well-stocked machine park, combined with good work organization, allow us to meet the most demanding orders and requirements. We provide services based on our own or provided by your projects.

During production, we place our attention on the effective use of materials, which allows for the minimising of costs for our clients.

In addition, thanks to our knowledge and experience, we can provide advice during the implementation of projects. All this at a competitive price, while ensuring quick service performance and a professional logistics process.

INDIVIDUAL SERVICE

The goals we set for ourselves are comprehensive service for both individual and cooperative clients.

EXPRESS IMPLEMENTATION AND DELIVERY

If you care about time, professional customer service, and quick delivery, contact us today! All of our services take place in our warehouse in Poland. However, based on our experience and excellent cooperation with logistics companies, we can guarantee quick delivery of completed orders.

COMPETITIVE PRICES

We provide competitive prices. Contact us for a specific quote – we guarantee you will be satisfied!

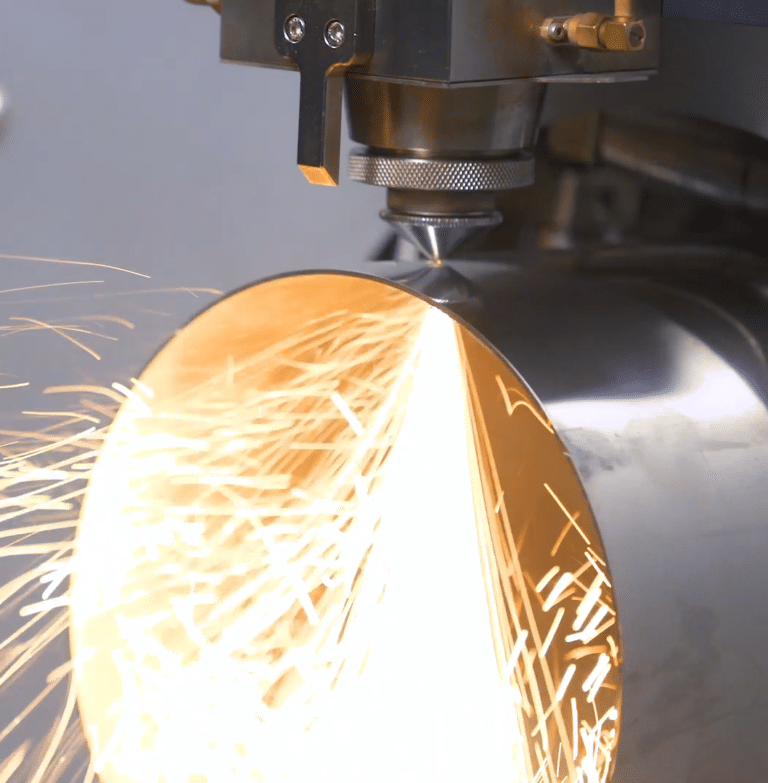

- Laser cutting - the biggest advantage of this solution

Laser cutting is an innovative way of processing a variety of materials, not only metal. Regardless of the raw material, the quality of the cut edge will be at the highest level. The directed beam precisely hits the marked area on the project. For this reason, it is not necessary to spend time or resources on any finishing stages. The technology ensures the highest quality and repeatability of details. At the same time, there is a particularly low risk of damage the product. Therefore, there is no material loss.

- The purpose of metal sheets laser cutting

Other methods of metal processing, such as plasma cutting or waterjet cutting, are not as effective as laser cutting. Numerical control makes it possible to adjust the parameters for each project. It also cuts into simple and complex forms. As a company, we also ensure timeliness and quick completion of work, as we know that time is priceless for many of you.

While cutting thin steel, laser cutting works perfectly because it shortens the service time. A powerful beam of light is concentrated in a limited area of only a few millimetres. This is done remotely for security reasons. It also has another advantage: the machine’s software allows you to make changes at any stage of production, which saves time and resources in the event of sudden changes in the design.

- LASER CUTTING OF PIPES, SQUARE PROFILES AND TUBES BY ELEKTRON

ELEKTRON is a leader in the market of companies offering services related to the processing and production of metal structures. We know everything about metal production and processing. In our offer you will find, among others, bending, cutting, grinding, and even straightening and subsequent coating of each element using the powder coating method. We provide all these services thanks to one of the most modern machinery parks in Poland. We can commit that your order will be completed with the highest quality and professionalism, delivered to you at a low cost and in a short time regardless of your location, and all that to meet all of your requirements.

- 3D LASER CUTTING - PIPES AND METAL PROFILES

We have already mentioned our modern machine park, but we have not said what makes it so special. Well, the element that decisively distinguishes us from the competition is precisely the high technological progression. We perform laser cutting of pipes and metal profiles using a professional Laser. What distinguishes the use of the laser cutting technique, especially traditional methods, is its reduced time needed to perform the task, as well as increased detail and precision. We work with various types of materials. We cut pipes and profiles made of brass, copper, and aluminium, as well as those made of stainless steel and chrome-nickel.

We offer two different types of services related to laser cutting of profiles: laser cutting of square profiles 20 × 20 and 150 × 150 with a length of up to 6500 mm; and 3D laser cutting of other tubes with a diameter not exceeding 210 mm (e.g., 150 × 20 mm). Our professional equipment has the option of automatic loading (3600–6500 mm long) and material unloading (3000 mm), while the maximum thickness of the cut varies depending on the material. In the case of black steel, it is 8 mm, stainless steel 5 mm, brass and aluminium 3 mm, while the thickness of the copper element cannot exceed 2 mm. We perform laser cutting of steel, aluminium, or brass profiles and pipes based on many years of experience in the industry and the highest quality processing equipment. Our experts have perfected every aspect of the laser cutting process by trial and error. We have a lot of completed projects and a multitude of satisfied customers, which you and your company can become part of.

- SUMMARY

If you need a professional laser cutting service contractor, you should choose our company. Each client, regardless of whether it is an individual client or a company, can count on the quick completion of work and attractive terms and conditions of cooperation. Our specialists will make a quick valuation for you and will undertake any laser cutting project, including complex ones. The equipment used by our employees is a TRUMATIC laser and a cutter in the L3050 variant with a power of 5 KW. These are the highest quality machines that are characterised by extraordinary quality and accuracy of cutting. Thanks to this, it is possible to cut sheets with a thickness of up to 25 mm. Laser cutting is a thermal treatment, but it does not cause deformation or loss in the material used. The laser is sometimes used by artists, designers, and engineers. Thanks to it, prototypes can be produced or used in industrial production. It guarantees repeatability of all cut elements. If you choose our services, you will benefit from the extensive knowledge and experience of our specialists in this field. Our employees constantly take part in training and projects, thanks to which they can operate the most advanced machines. As a company, we pay special attention to timeliness, thanks to which we collect positive feedback from our satisfied customers all over the EU.