For laymen, sheet metal bending with a press brake may seem like a very niche and unpopular service. However, not everyone is aware of how often this method is used in production processes. Sheet metal bending with a press brake is an indispensable part of the industry and the production of all possible products made of metal or sheet metal. You can even risk a statement that sheet metal bending is a process that is almost indispensable during the mass production of steel elements.

Do you want to learn more about sheet metal bending, find out how often it is used in production, and surprise your friends with the enormity of your knowledge? We will try to make it easier for you and present all the most important information in a nutshell.

What does sheet metal bending look like during the production of steel elements?

Sheet metal bending is the process of influencing the plane to change the shape of the sheet using appropriate pressure and force, resulting in a permanent change in the curvature of the bent sheet. Importantly, sheet metal bending does not lead to a significant difference in the quality, thickness, or properties of a given sheet. The bending procedure allows for the free formation of elements bent into relatively complex shapes. Due to bending, it is possible to obtain a sheet with a large number of bends of various sizes, which is extremely useful in the production of steel and metal elements. It is also worth remembering that sheet metal bending is a whole set of various plastic forming services, such as bending, straightening, and coiling sheets of various shapes and thicknesses.

What does sheet metal bending look like with a press brake?

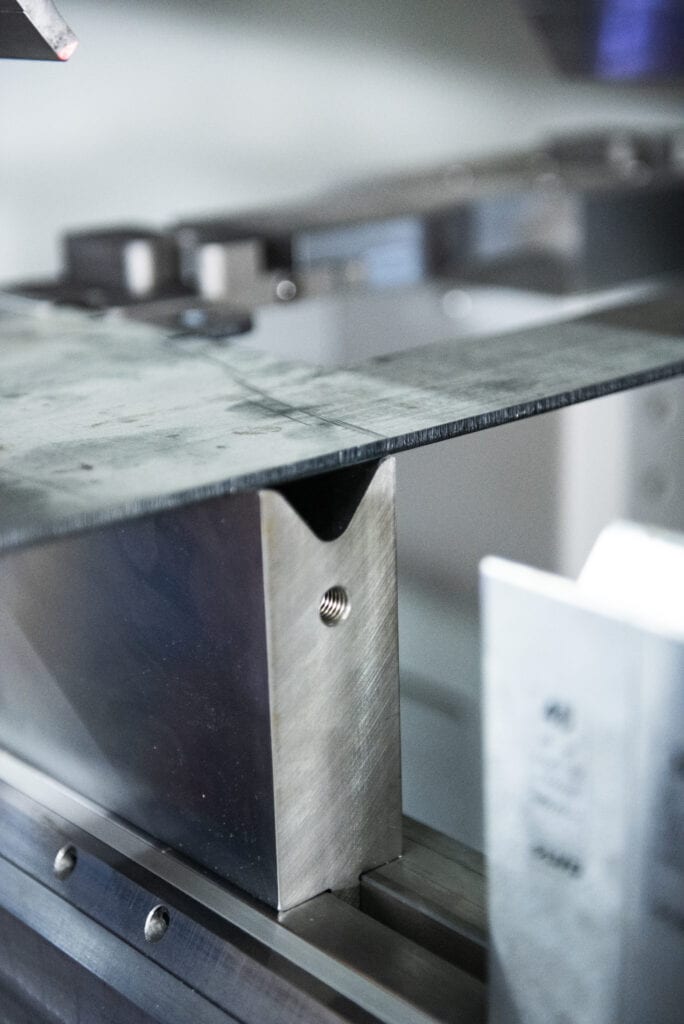

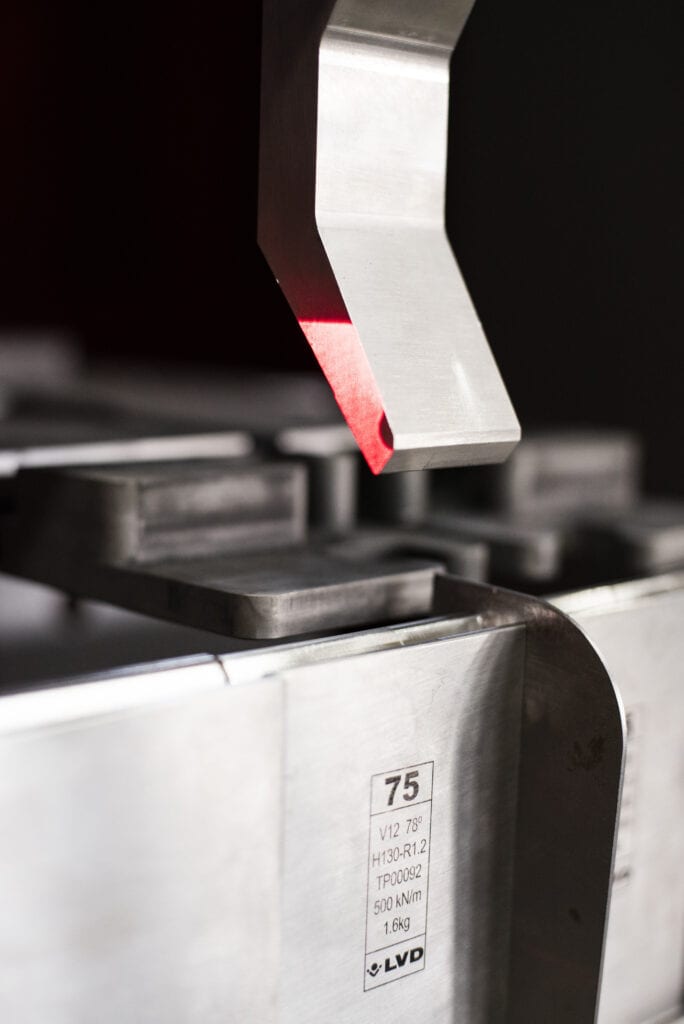

Sheet metal bending with a press brake is designed to form flat sheets of metal and change their appearance to the desired shape. Most often, this type of machining is started immediately after the sheet is cut to the appropriate size, and the workpiece in the press brake is placed on the die. At a later stage, the stamp presses against the element, changing its shape.

A press brake, often called a folding machine, is a high-class, leading tool for sheet metal bending, characterised by a high degree of precision and repeatability of bending, which is why this type of plastic forming machine is most often used for the production of steel elements, as well as those made from other types of metal materials. The use of a press brake, equipped with appropriate punches, forms, and dies, allows for folding and bending the sheet at any angle, but the most important advantage is that the folding mechanism allows you to obtain many identical bends on different sheets of metal.

Most of the elements made of sheet metal are processed with a press brake, and it is a key element in the production of steel elements. This service is most often used:

- In the construction industry—window sills, eaves, gutters, plumbing,

- When creating car and motorcycle bodies, tractors, semi-trailers, and car trailers,

- In the production of construction elements

- parts of machines and devices used in factories and enterprises of all types,

- In the production of everyday appliances and home furnishings,

- In the shipbuilding and shipbuilding and aircraft industries,

- In the production of metal furniture,

- In the production of decorations

- During the production of GSM, RTV, and household appliances, main housings,

- During the production of fences, gates, and fences