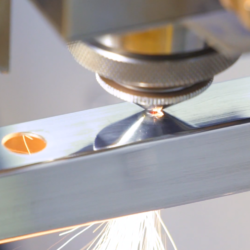

What are the important techniques of metal fabrication for which knowledge is essential?

The engineers and technicians responsible for metal manufacture have access to a wide variety of metal fabrication techniques. The three most widely used methods for fabricating metal are cutting, forming, and welding. These fabrication methods can be further broken down into sub-categories such as laser cutting and shearing, bending and stretching procedures, and MIG and[…]