We specialise in metal processing

Elektron is a limited business as well as a limited partnership. The Elektron Corporation is a modern corporation that has been rapidly growing in the metal processing business since 2018.

We have over 100 skilled and trained team members who help us deliver the best service possible.

Our warehouse is intended for metalworking.

On average, we implement 54 projects per month.

Comprehensive Materials Processing

Elektron is a company that offers laser cutting, sheet metal bending, pipe and metal profile bending, welding, and powder coating, among other services. We have professional knowledge that we are constantly increasing, even though we are a young organisation. Our experience enables us to meet even the most demanding client requirements and requests. We provide a diverse choice of products and services, all of which are backed by excellent customer service.

We are constantly developing our capabilities

Our facilities are continually being expanded, and we are accumulating experience. We are willing to work with you on any project. Because of our previous expertise and facilities, we are able to maintain high quality standards and thereby satisfy a large number of clients.

Our Services

Professional project services

Metal processing

Laser cutting

Cutting and threading in metal

Welding

Surface Preparation

Product finishing

Assembly / Preparation for shipment

Logistics

Quality control

Comprehensive implementation of all projects is guaranteed by our specialised team consisting of:

- 4 Project Managers

- 5 Technologists and Designers

When implementing projects, we use software that speeds up and guarantees comprehensive project service.

We work on software such as:

- CAD / CAM software

- Lantek

- Autocad

- Solidworks

- Sigma Tube

- Artube

- Blender

Modern technology guarantees repeatability and precision in realization of even the most complex elements

Thanks to the extensive practice in our offer you can find:

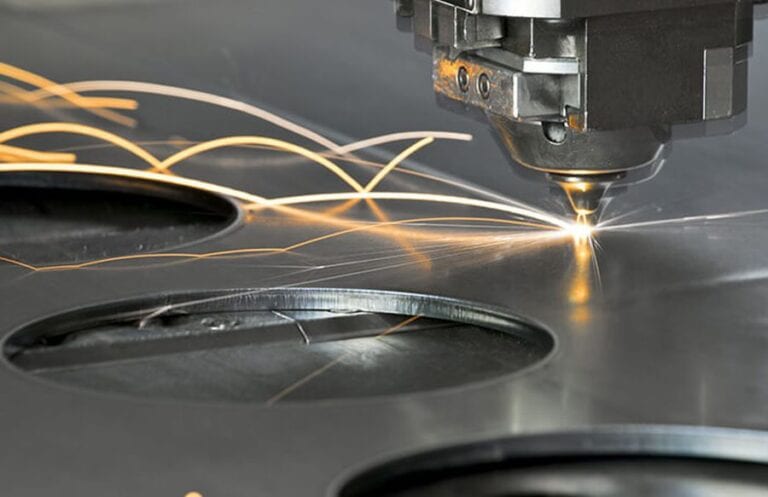

- Laser cutting up to 25 mm of mild steel and up to 12 mm of stainless steel

- Guillotine cutting up to a maximum length of 2000 mm and a thickness of 3 mm

- Bending of sheets with a maximum length of 3000mm and a maximum thickness of 6mm

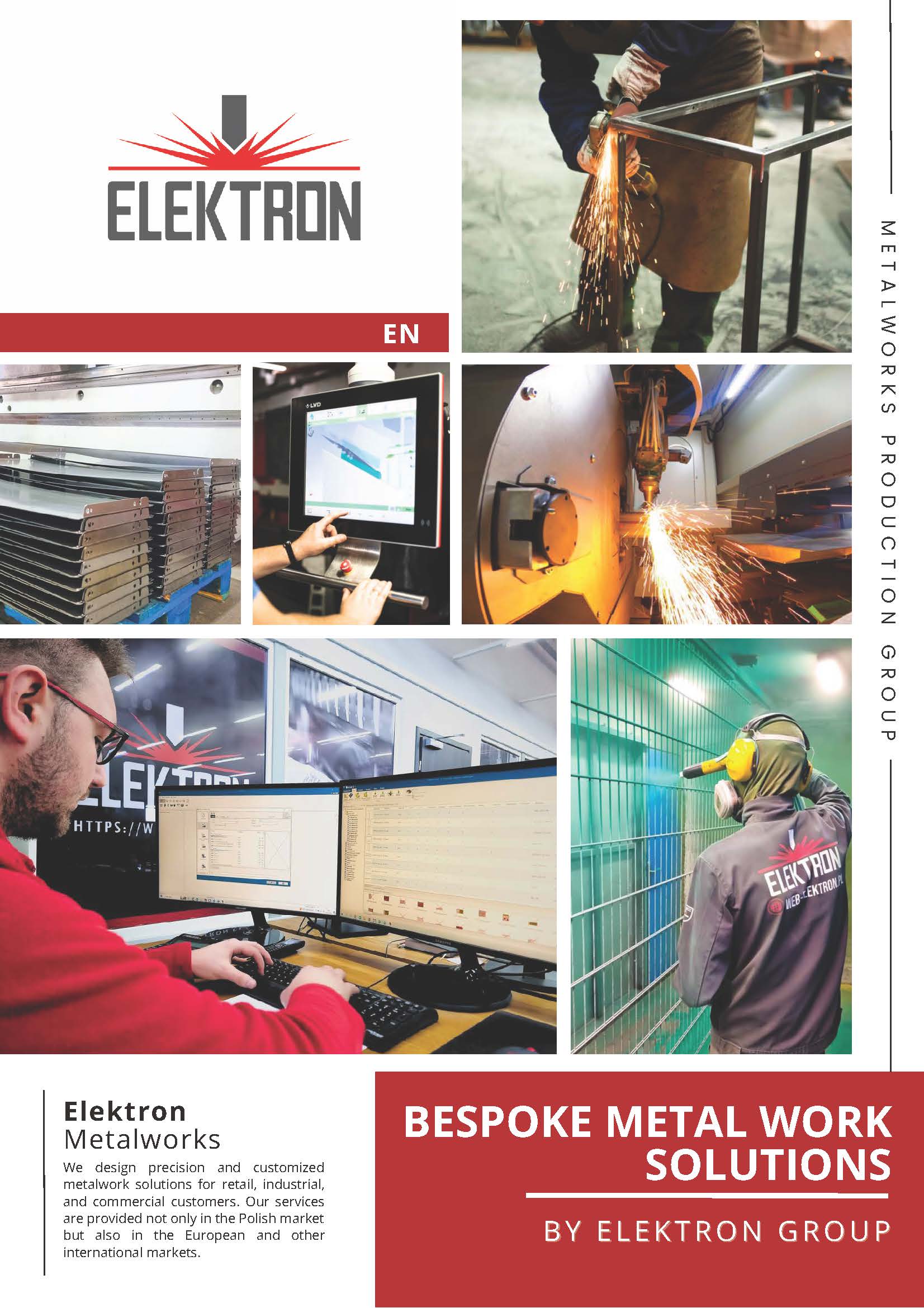

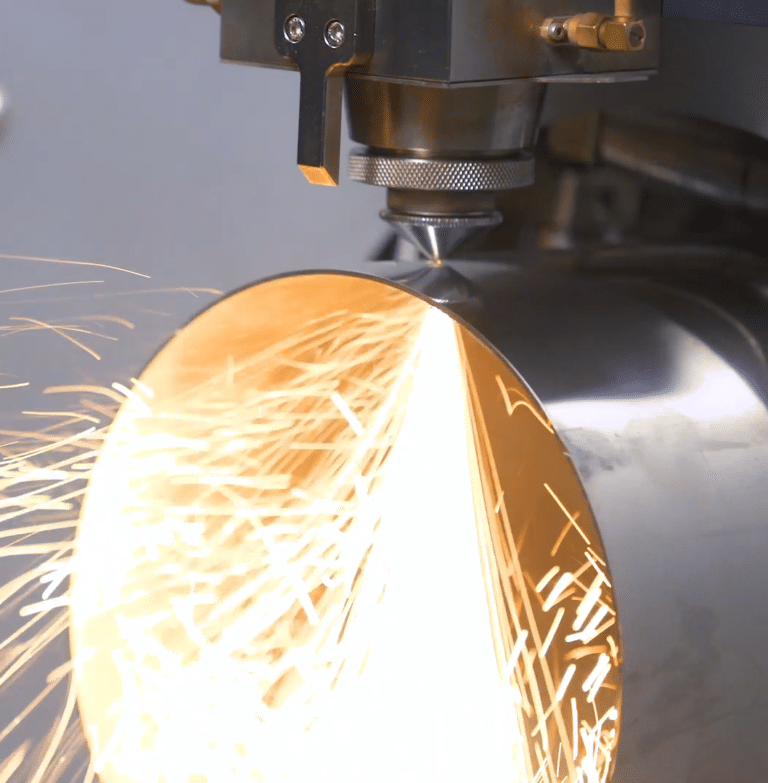

Laser cutting is a thermal treatment process that concentrates the energy of a strong laser beam onto very small surfaces (0.1 to 0.5 mm). It is an exceptionally fast, reliable and flexible method of working with material, because it significantly shortens production cycles.

Laser cutting is primarily used for thin sheets to quickly produce simple and complex shapes from various types of materials up to 25 mm thick, while maintaining a very high level of precision. Additionally, thanks to a very focused beam, laser cutting of sheet metal does not cause deformation or material loss – it is characterized by excellent efficiency.

Our offer also includes the processing of sections in the form of bending pipes and profiles using a mandrel bender. Bending of pipes and profiles using CNC machines guarantees repeatability and the ability to produce a large number of details in a short time. Thanks to the advanced pipe and profile bending machine numerically controlled, the process is optimized to such an extent that we can offer details at a very competitive price. The bending machine is suitable for bending very large batches, thanks to which no order is scary for us.

Using modern machines, we optimize the metal threading process, which allows to significantly minimize production costs while maintaining the highest precision.

Welding of steel and stainless steel using MIG / MAG and TIG methods, and spot welding.

- 9 welding stations (MIG / MAG, TIG)

- Spot welder

Before the end of the production process, each product requires surface preparation.

In order to protect the product from corrosion and to provide its final appearance, an appropriate coating is being applied to each product.

- Powder painting

- Electroplating

- Hot dip galvanizing

For us, the most important thing is quality.

Thanks to the implemented management systems, we offer products of the highest quality. Our team of quality controllers supervises the production process and guarantees precise execution.

At the installation stage, an experienced team of fitters and electricians not only connect metal to other elements, but also enrich the structure and other non-metal components.

We combine metal with PVC, wood and glass, among others, and we also make electrical installations.

Packaging is adjusted individually to the product type and size.

We will deliver the products to the address you specify, regardless of the location.

Comprehensive implementation of all projects is guaranteed by our specialised team consisting of:

- 4 Project Managers

- 5 Technologists and Designers

When implementing projects, we use software that speeds up and guarantees comprehensive project service.

We work on software such as:

- CAD / CAM software

- Lantek

- Autocad

- Solidworks

- Sigma Tube

- Artube

- Blender

Modern technology guarantees repeatability and precision in realization of even the most complex elements

Thanks to the extensive practice in our offer you can find:

- Laser cutting up to 25 mm of mild steel and up to 12 mm of stainless steel

- Guillotine cutting up to a maximum length of 2000 mm and a thickness of 3 mm

- Bending of sheets with a maximum length of 3000mm and a maximum thickness of 6mm

Laser cutting is a thermal treatment process that concentrates the energy of a strong laser beam onto very small surfaces (0.1 to 0.5 mm). It is an exceptionally fast, reliable and flexible method of working with material, because it significantly shortens production cycles.

Laser cutting is primarily used for thin sheets to quickly produce simple and complex shapes from various types of materials up to 25 mm thick, while maintaining a very high level of precision. Additionally, thanks to a very focused beam, laser cutting of sheet metal does not cause deformation or material loss – it is characterized by excellent efficiency.

Our offer also includes the processing of sections in the form of bending pipes and profiles using a mandrel bender. Bending of pipes and profiles using CNC machines guarantees repeatability and the ability to produce a large number of details in a short time. Thanks to the advanced pipe and profile bending machine numerically controlled, the process is optimized to such an extent that we can offer details at a very competitive price. The bending machine is suitable for bending very large batches, thanks to which no order is scary for us.

Using modern machines, we optimize the metal threading process, which allows to significantly minimize production costs while maintaining the highest precision.

Welding of steel and stainless steel using MIG / MAG and TIG methods, and spot welding.

- 9 welding stations (MIG / MAG, TIG)

- Spot welder

Before the end of the production process, each product requires surface preparation.

In order to protect the product from corrosion and to provide its final appearance, an appropriate coating is being applied to each product.

- Powder painting

- Electroplating

- Hot dip galvanizing

For us, the most important thing is quality.

Thanks to the implemented management systems, we offer products of the highest quality. Our team of quality controllers supervises the production process and guarantees precise execution.

At the installation stage, an experienced team of fitters and electricians not only connect metal to other elements, but also enrich the structure and other non-metal components.

We combine metal with PVC, wood and glass, among others, and we also make electrical installations.

Packaging is adjusted individually to the product type and size.

We will deliver the products to the address you specify, regardless of the location.

Download our catalog for more details!

In the offer, you will find all the details of our products:

- Detailed description of the products

- Types of materials

- Who we are?

- Services

- Projects examples

- Application

Do you have any questions about us? Please don’t hesitate to get in touch with us!

Laser cutting of sheet metal, profiles, and pipes-error-free and fast

Our speciality is laser cutting, which allows us to achieve perfectly even edges while maintaining remarkable detail and repeatability of the obtained elements. We work on modern, high-quality equipment that comes from the factories of reputable manufacturers. Laser cuts are precise operations, which is why they are ideal for industries where it is important to process the metal to obtain the same product accurately.

We guarantee 100% repeatability. Such a high quality of work is possible thanks to the combination of modern machinery and effective technologies with a qualified team of professionals who have many years of practice and can boast of many professional and enthusiastically accepted projects. When ordering laser cutting services from our company, you can be sure that we will execute the order by the agreed date and that the effect will fully satisfy the customer.

What Laser metal processing service do we offer?

The catalogue of Elektron services is very extensive. We operate comprehensively, and thanks to this, we will find help for entrepreneurs operating in various industries. We use 2D (flat models) and 3D (three-dimensional models) processing technology. Our specialists offer, among others:

- sheet metal, laser cutting,

- laser cutting of profiles,

- laser cutting of pipes,

Various patterns in metal, e.g., decorative elements, can be laser cut.

We work with various materials. We offer laser cutting services for carbon steel, stainless steel, aluminium, brass, and copper. We accept models of various thicknesses and shapes for processing. Our projects are not limited to objects with straight lines; we also undertake tasks related to irregular and unusual shapes.

CNC cutting-error-free, precise and fast

We are a real competitor in the market because we provide our clients with elements of identical dimensions. Our work is as precise as possible and the effects are repeatable. To what do we owe such professional action? Not only the qualifications and experience of the team allow us to achieve the best possible work results, but also the use of the most modern and accurate metal processing technique, which is CNC cutting.

It is an operation using numerical control technology. This means that the laser cutting of sheet metal and laser cutting of profiles or pipes is carried out with the help of a machine controlled by a special computer. It is therefore an automatic operation and not a manual one. CNC laser cutting of metal is not performed by a specialist – traditional hand-held devices are not used. This means that the work is free from so-called human error.

Manual metal processing involves a large margin of error. A delicate, even imperceptible at first glance, step beyond the template is enough, and the manufactured elements will differ. With manual techniques, there is practically no chance of maintaining repeatability. These are activities that are not applicable in industries where exceptional precision is essential. Therefore, if you want to obtain finished products, it is worth commissioning us to laser cut metal with the use of numerical control.

Metal processing using the CNC method

Although CNC technology allows you to achieve the most precise results in your work, few people know what it is. The abbreviation comes from the English name “computerised numerical control,” which means computerised control of numerical devices. The machines used are equipped with a microcomputer, which is designed to manage and control their movements.

CNC metal processing consists of three stages:

- creating a computer project,

- its edition,

- making the element (excellent work).

In the first stage, special software is used that allows you to enter detailed data on dimensions, cutting angles, distances, edge thickness, etc. The goal is to create a project, i.e. a task for the machine. The entered command must be properly processed, for which the appropriate algorithm is responsible. The design is adapted to the capabilities of the machine tool and the nature of the material. The application includes, among others, factors such as surface roughness, local convexities, etc. The microprocessor edits the model data entered by the operator so that it corresponds to the real environment in which the machine will operate, allowing them to achieve the best effect.

The final step is to carry out the work through the device. All his movements are controlled by a computer. The metal laser cutting itself is done without human intervention. Its role is reduced to that of the operator. He is responsible only for entering data into the computer, i.e. programming the machine, and creating a command. Metal processing is performed automatically. That is why it is repetitive and error-free work, ensuring the highest possible quality.

Advantages of our CNC laser cutting

The greatest benefits are, of course, the ability to maintain impressive precision, and thus obtain 100% repeatability when creating subsequent elements, i.e., obtaining the same ready-made items.

Another benefit is that it saves time. CNC laser cutting of sheet metal, profiles, pipes, or any other sort of metal processing is far faster than manual operations. Unlike humans, the machine does not become tired or require rest. However, the most important feature is that the data entered by the operator into the computer is saved, eliminating the need to manually program the device at successive laser activations.

such fast work allows us to significantly shortens the time needed to complete the order. Thanks to this, our clients can receive ready-made elements much faster than would be the case when working with traditional manual devices.

Ordering laser cutting appears to be a more expensive service on the surface, but it saves you money. What does it mean that this is possible? The machine’s flawless performance translates into the ability to make good use of virtually every received element, eliminating material losses, which is a common concern for clients ordering processing with hand tools.

With manual services, you will never achieve the same items, and in many industries, even minimal deviations render the model unusable and simply thrown away. CNC laser cutting is free from such hassles, which means losses, which usually involve the need to place another order to compensate for material shortages. Ultimately, the costs incurred are much higher than the cost of laser metal processing.

Laser cutting - principle of operation

A laser for cutting metal gives by far the best effect of any other technology. This technique produces the smoothest edges and, above all, is suitable for working with fine details and allows you to create any shape based on irregular lines. This is possible because the resulting cutting gap is only microscopically larger than the laser beam itself. This translates into a degree of precision so high that it is possible to create even complex geometric patterns.

Laser cutters are equipped with integrated diodes. They are responsible for producing the laser beam. Thanks to specially designed and extremely flexible optical fibres, it is then transported to the head, from which it is transferred to the material being processed. The stream drops to the surface, causing it to be heated until completely vaporized. Therefore, laser cutting uses the phenomenon of thermal separation. Its beam must penetrate the object as deeply as possible in a single location. When this happens, the actual cutting process begins, i.e., separating the material. It is happening at lightning speed.

Laser cutting in metal - the advantages of using laser tools

The use of numerical control technology guarantees repeatability and error-free performance of the work. What are the advantages of laser metal cutting? It is a universal method, first of all. It can be used for machining various types of materials, e.g. steel, aluminum, brass, or copper. No other techniques are is widely used.

There are also no restrictions on the shape of the models to be worked on. Laser cutting can be performed on objects with straight lines as well as objects distinguished by irregular shapes.

The CNC allows you to shorten the time needed to complete the work. When this technology is used with laser cutters and not others, the job can be completed even faster. Laser processing of metals leaves perfectly smooth edges that do not require any finishing work such as grinding or polishing. When the component is removed from the machine, it is finished and ready for use. Thanks to this, the customer can pick up their order much faster.

How are we doing?

With each order that we accept from clients, we conduct a thorough interview with the client. Our ambition is to provide elements that will fully satisfy the expectations of our contractors, which is why we want to know their visions and needs. We also offer help and suggest the best solutions.

We always carry out the valuation individually to be able to offer the fairest possible offer. The price is adjusted to the scale of the difficulty, which determines the degree of involvement in the work. The lack of a fixed price is a plus because customers ordering simple actions do not overpay, as would be the case with the use of constant costs depending, for example, only on the number of workpieces.To obtain the highest quality and quick implementation, there is no need to look for advertisements such as “I will order laser cutting.” It’s best to contact us right away. We look forward to working with you!